Winter Checklist for Work Vans and Commercial Vehicles

17th Feb 2026

Recent winter storms and freezing temperatures have made road conditions unpredictable across much of the country. For loaded work vans, this increases safety risks during daily jobsite travel.

Prepare Your Work Van for Winter Conditions

Cold weather places added demands on vehicles that carry tools, materials, and equipment every day. Cargo weight affects stopping distance and stability, while snow and ice strain batteries, tires, and visibility systems.

This winter driving checklist outlines practical steps to improve safety, protect equipment, and keep jobs moving throughout harsh winter conditions.

Winter Driving Basics for Work Vans

Winter driving advice often assumes an empty passenger car, but a fully loaded work van can weigh significantly more than a standard vehicle. This extra weight increases stopping distance and changes how the van responds when traction drops.

Here’s what that means in real terms:

Winter driving advice often assumes an empty passenger car, but a fully loaded work van can weigh significantly more than a standard vehicle. This extra weight increases stopping distance and changes how the van responds when traction drops.

- Stopping distance increases dramatically on icy roads when carrying heavy equipment.

- Weight concentrated on one side of the van can affect balance during sudden maneuvers.

- Unsecured tools can shift under hard braking, changing vehicle stability mid-stop.

Instead of simply “driving slower,” adjust your driving with your load in mind:

- Leave additional braking distance beyond standard winter recommendations.

- Brake earlier and more gradually.

- Avoid abrupt steering inputs that shift internal cargo weight.

- Be especially cautious on bridges and shaded areas where black ice forms first.

If your van begins to skid, smooth inputs matter. Ease off the accelerator and steer gently in the intended direction of travel. Sudden corrections can amplify instability when cargo weight shifts.

Safe winter driving requires managing traction while accounting for cargo weight and balance.

Inspect Your Vehicle Before Winter Driving

Cold weather exposes weak points in your van. A breakdown during winter can delay jobs, disrupt your schedule, and create unnecessary downtime.A proactive inspection helps reduce those risks.

Tires: Your First Line of Defense

Cold air reduces tire pressure by roughly 1 PSI for every 10°F temperature drop. Lower pressure affects traction, steering response, and braking performance — especially in a loaded work van.

Before and throughout winter:

- Measure tread depth

- Check tire pressure monthly

- Inspect for uneven wear

- Consider winter tires if you regularly operate in snow-heavy areas

Tire condition directly impacts stopping distance and vehicle control on snow and ice. In a cargo van carrying tools and materials, maintaining proper traction is critical to safe handling.

Battery Performance

Cold weather reduces battery output while increasing the power required to start your engine. Vans that start reliably in mild temperatures can struggle during freezing mornings. If your battery is more than a few years old or slow to turn over, have it tested before sustained cold sets in. A failed start can delay your first job of the day and disrupt your schedule.

Fluids and Visibility

Winter driving often involves salt spray, slush buildup, and low visibility. Before and during the season:

- Top up winter-grade windshield washer fluid

- Inspect wiper blades for streaking or cracking

- Check coolant and antifreeze levels

- Confirm headlights, brake lights, and hazard lights are functioning properly

Maintaining clear visibility improves reaction time in snow, freezing rain, and heavy traffic conditions.

Fuel Levels

Keep your fuel tank at least half full throughout winter. A fuller tank helps reduce condensation inside the fuel system and gives you flexibility if traffic slows during storms or you encounter road closures.

Running low on fuel in freezing conditions creates unnecessary risk and downtime.

Protect Tools and Equipment in Winter Conditions

Winter driving increases the likelihood of hard braking, sudden stops, and reduced traction. When that happens, unsecured tools and materials move. Inside a cargo van, shifting equipment can:

- Slide into doors and panels

- Damage other tools

- Loosen mounts or brackets

- Create additional safety risk during a stop

- Moisture adds another layer of exposure. Snow-covered boots, wet materials, and condensation from temperature swings can accelerate rust and corrosion inside the cargo area.

A secure storage setup reduces that movement.

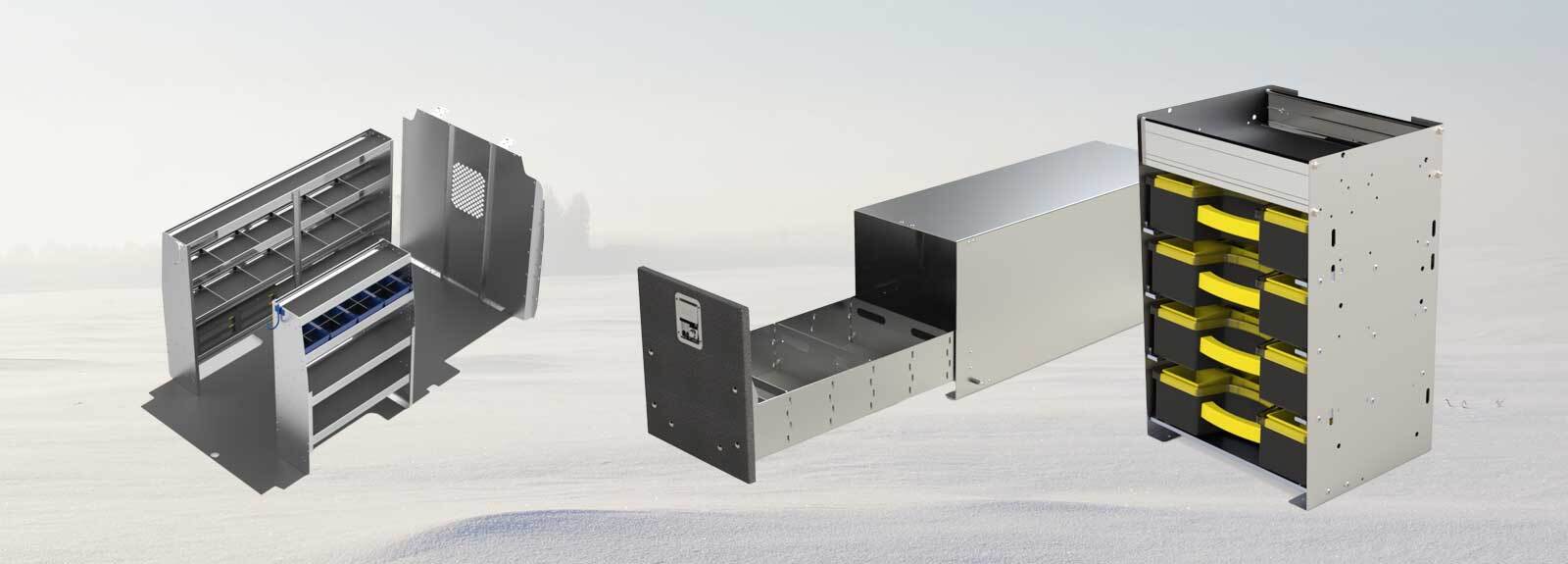

Using properly fitted cargo van shelving systems helps keep larger tools stable and contained. Shelving designed for your specific van model improves fitment, reduces gaps, and maintains aisle space for safe access.

For smaller parts and hardware, dedicated work van drawer systems or compartmentalized bins prevent items from scattering during braking. Drawers keep fittings, fasteners, and components organized and accessible, even in rough road conditions. Winter conditions increase stress on both the vehicle and its contents. Securing your layout protects your tools, supports safer handling, and reduces avoidable damage throughout the season.

Storage Features That Improve Winter Safety

Winter driving places additional stress on your vehicle and its cargo area. A secure storage setup can help reduce tool movement and internal damage during hard braking on icy roads. Features that support winter driving safety include:

- Shelving designed to fit your specific van model

- Drawer systems that prevent small parts from shifting

- Partitions that separate the cargo area from the cab

- Storage accessories that reduce moisture buildup

Secure, well-fitted storage helps keep your van stable and your tools protected during winter driving.

Stock a Winter Emergency Kit for Your Work Van

Winter storms in the Northeast can slow traffic for hours and make roadside conditions unpredictable. Keeping essential supplies in your van reduces risk if you’re delayed, stuck, or waiting for assistance. Snow, black ice, and icy roads increase the likelihood of breakdowns and traffic standstills during winter weather. A well-prepared vehicle should carry a dedicated emergency kit throughout the season.

Recommended items include:

- Ice scraper and de-icer

- Compact shovel

- Jumper cables

- Flashlight with extra batteries

- Phone charger or portable battery pack

- Reflective warning triangles

- Blanket and insulated gloves

- Water and non-perishable snacks

- Basic first aid kit

- Traction aid such as sand or kitty litter

Store emergency supplies in a consistent, easy-to-access location — not buried beneath tools or materials. If your van becomes a broken-down vehicle in cold temperatures, access matters. Review your emergency kit periodically and replace used or depleted items. Winter conditions change quickly, and preparation supports safer decision-making when visibility, traction, and road conditions deteriorate.

Cold Weather Maintenance Checklist

Winter preparation doesn’t end after the first storm. Ongoing exposure to snow, ice, road salt, and cold weather gradually wears down key parts of your vehicle.

Add the following checks to your regular winter driving checklist throughout the season.

1. Manage Road Salt and Corrosion

Road salt improves traction on icy roads but accelerates corrosion underneath your van.

- Wash the undercarriage regularly to remove salt buildup

- Rinse lower door panels and step areas

- Inspect the cargo floor and mounting points for early rust

Salt accumulation can weaken hardware and shorten the lifespan of shelving and storage components if left untreated. Material choice also plays a role in long-term durability. In regions where road salt is heavily used, aluminum shelving systems offer increased resistance to rust compared to traditional steel components, helping reduce corrosion-related wear over time.

2. Inspect Seals, Locks, and Moving Parts

Freezing temperatures affect rubber seals and mechanical components.

- Check door seals for cracking or stiffness

- Lubricate locks to prevent freezing

- Inspect hinges and latches for stiffness or buildup

Moisture combined with cold temperatures can cause sticking doors and reduced access to tools when you need them most.

3. Monitor Tire and Spare Condition

Cold air continues to affect tire pressure throughout winter weather.

- Recheck tire pressure regularly

- Monitor tread depth for safe traction

- Inspect your spare tire to ensure it’s properly inflated

- A neglected spare can create additional delays if you experience a flat during snow or freezing rain.

4. Evaluate Overall Vehicle Condition

Winter driving places added strain on your vehicle’s systems.

- Listen for unusual vibrations after driving on rough or icy roads

- Check for loose shelving mounts or hardware

- Monitor for slow starts that may indicate battery strain

Small maintenance checks throughout the season reduce the risk of becoming a broken-down vehicle during severe winter conditions

Quick Winter Driving Checklist

Use this quick reference as part of your regular winter driving checklist to keep your work van ready for snow, ice, and cold temperatures.

Before Every Trip

- Check tire pressure and overall tire condition

- Confirm headlights, brake lights, and hazard lights are functioning

- Secure tools and materials to prevent shifting on slippery roads

- Verify emergency kit supplies are accessible

- Review weather conditions and road advisories

Weekly

- Inspect battery performance, especially during extended cold weather

- Top up windshield wiper fluid and check blade condition

- Clean lights, mirrors, and windows for visibility in snow and freezing rain

- Check cargo area for moisture buildup or loose equipment

Monthly

- Measure tread depth to maintain traction on icy roads

- Inspect undercarriage and mounting points for road salt corrosion

- Check spare tire pressure and condition

- Reassess storage layout to ensure equipment remains secure

Winter Driving Checklist FAQs

Do I need winter tires for a work van?

Winter tires provide improved traction in snow, slush, and icy roads because they use a softer rubber compound and deeper tread patterns designed for cold temperatures. If you regularly drive in winter weather, especially during heavy snowfall or freezing rain, winter tires can improve braking performance and vehicle stability — particularly in a loaded work van.

How often should I check tire pressure in winter?

Cold temperatures reduce tire pressure by roughly 1 PSI for every 10°F drop. Lower pressure affects traction, handling, and fuel efficiency.

Check tire pressure at least once a month and before long trips during winter conditions. Maintaining proper inflation helps improve control on slippery roads.

Why does my van battery struggle in cold weather?

Low temperatures reduce battery output while increasing the power required to start the engine. A battery that performs reliably in warm months may weaken during freezing conditions. Testing and replacing a weak battery before peak winter weather reduces the risk of becoming a broken-down vehicle on a cold morning.

What should I keep in a winter emergency kit for my van?

A winter emergency kit should include an ice scraper, shovel, jumper cables, flashlight with extra batteries, blanket, gloves, water, snacks, a first aid kit, phone charger, and traction aids like sand or kitty litter. These essentials help you handle delays caused by snow, black ice, or winter roadside breakdowns.

Why should I keep my fuel tank at least half full in winter?

Keeping your gas tank at least half full reduces condensation inside the fuel system, which can freeze during cold weather. A fuller tank also provides flexibility if winter storms slow traffic or cause unexpected detours.